99.9% Centralized Extraction Solution for Welding Ksdc-8606b1 Fume Extractor

Basic Info

| Model NO. | KSDC-8606B1 |

| Air Volume | 12000±100m³/H |

| Inlet Air Flow | 9500m³/H |

| Voltage | 460V/60Hz |

| Motor Power | 11kw |

| Filter Area | 90m² |

| Filtering Efficiency | 99.9% |

| Filtering Precision | ≥0.1μm |

| Filter Cartridge | 6PCS |

| Solenoid Valve | 6PCS |

| Cleaning Way | Automatic |

| Compressed Air | 0.5-0.6MPa |

| Noise | ≤72dB(a) |

| Weight | 1120±20kgs |

| Certificate | CE |

| Transport Package | Wooden Case |

| Specification | 1620*1750*2150mm |

| Trademark | Kaisen |

| Origin | Shanghai, China |

| HS Code | 8421399090 |

| Production Capacity | 30 Sets/Month |

Product Description

Technical parameters

| Model | 99.9% Centralized Extraction Solution for Welding KSDC-8606B1 Fume Extractor | |

| 1 | Fan type | centrifugal fan |

| 2 | Treatment of air flow | 12000±200 m3/h |

| 3 | Motor power | 11 kW |

| 4 | Power supply | 3×380V/50Hz or 460V/60Hz |

| 5 | Filtration area | 90m2 |

| 6 | Number of cartridge filters | 6 pieces |

| 7 | Filter medium | PTFE coated filter element |

| 8 | Filtration efficiency | >99.9% |

| 9 | Solenoid valve | 46pieces |

| 10 | Compressed air | 5~6 bar |

| 11 | Ash hopper volume | 25L |

| 12 | Noise | ≤72±5dB(A) |

| 13 | Weight | 1120±20kg |

| 14 | Dimensions(excluding suction arm) | 1620(L)×1750(W)×2150(H)mm |

Our advantages:

1. CE certification is available.

2. Application for small or medium plasma cutting fume disposal, under 3Kw laser cutting fume disposal.

3. Large air flow, automatically cleaning, maintaining easy, preprocessor to intercept the spark.

4. Good parts make sure the qualilty, for example, Siemens PLC and montoring screen, Japan Toray filtering material, AKZO Nobel spraying powder etc.

5. Exellent housing and structure design makes sure the machine is durable.

Application

Working principle

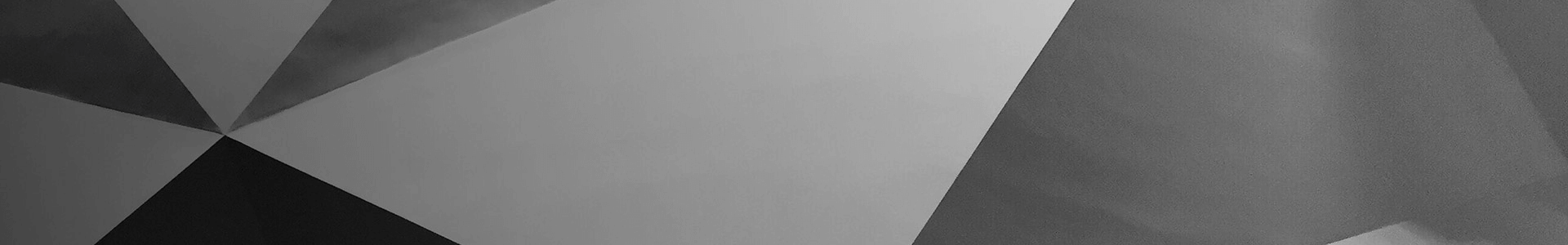

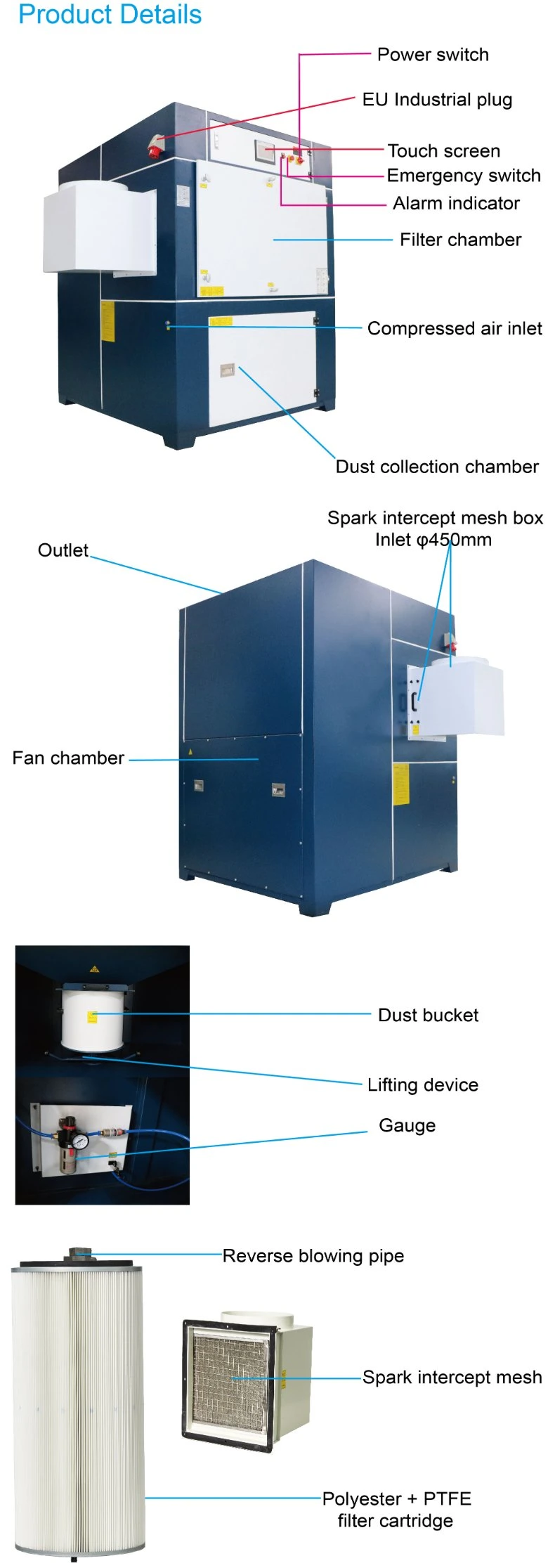

Dust laden fume are sucked into the extractor by the suction force induced by fan's working, with deflector fume's flowing speed is slowed, big practical and sparks are cooled, separated and then settle into dust collector. Fine fume and dust enter into filter compartment to be filtered by the filter cartridge. The filter cartridge is coated with PTFE film which is covered with uniform pores, it has good air permeability, and dusts are filtered out on its surface. Purified air enters into the filter cartridge's interior and then discharged into workshop directly or out of the workshop through pipe line.

Main features

Central Control system implements real-time monitoring and analysis on a number of important parameter of equipments in the operation and show them in the display, and it has self-diagnosis function, showing abnormal and error conditions in the operation of the equipment automatically. The central dust & fume purification system's performance is controlled by PLC controlling system.

Central fume&dust purifier is a series product researched, developed and designed by the company based on the requirements of different site conditions.The structure of integrated units is designed to compact and reasonable. A complete series of specifications has been developed to meet the on-site different work-in-conditions, whether large-scale welding or grinding shop, or welding centers, robotic welding production lines, plasma, or laser cutting blanking production lines, you can find suitable product model.

The functionality of a filter lies in the filter element's material, Kaisen's filter element is specially developed for the purification of fume and fine particles generated in welding and cutting, solved this industry's problem of low filtration precision and filter element's blocking. And the outer surface of the cartridge is covered by a layer of PTFE film layer through heat treatment a special process. Cartridge wall is thin in structure and has high strength, and the surface film layer has a very uniform pores, making a network structure with a bore diameter of 0.1 microns below

To the position polluted by a little oil mist, the company's special spray device not only dilutes oil mist and prevents the dust from attaching to the filter surface to reduce its service life, but also plays a role in fire prevention.

Certification

Company profileExhibition

If you need any further information, please feel free to contact us.