Basic Info

| Model NO. | ZM-shuixuan-PQF |

| Method Type | Automatic |

| Condition | New |

| Media | Water |

| Use | Paint Mist Treatment Equipment |

| Transport Package | Wooden Box |

| Specification | Water spinning spray paint room |

| Trademark | Zhangmeng |

| Origin | Zhejiang, China |

| HS Code | 8424300000 |

| Production Capacity | 3000set/Year |

Product Description

The so-called painting means covering the metal and non-metal surface with a protective or decorative layer. With the development of industrial technology, painting has been developed from manual to industrial automation, and the degree of automation is getting higher and higher, so the application of painting production line has become more and more extensive and penetrated into many fields of national economy.According to the characteristics of the workpiece and the process demand of coating, there are powder coating production lines, painting production lines, electrophoresis production lines and so on.The application range of coating production line is quite wide.Powder coating production line is widely used in most steel sheet industries such as home appliances, conveying, logistics, bicycle frames, elevators, etc.Paint spraying production line is widely used in industries such as wood, plastic products, shock absorbers, etc. where baking temperature is not easy to be too high or non-metal products.Electrophoresis production lines are widely used in industries with high surface treatment requirements such as auto parts.The coating production line is generally composed of seven parts: pre-treatment equipment, moisture drying equipment, coating spraying equipment, coating baking equipment, heat source system, product conveying equipment, electrical control system, etc.

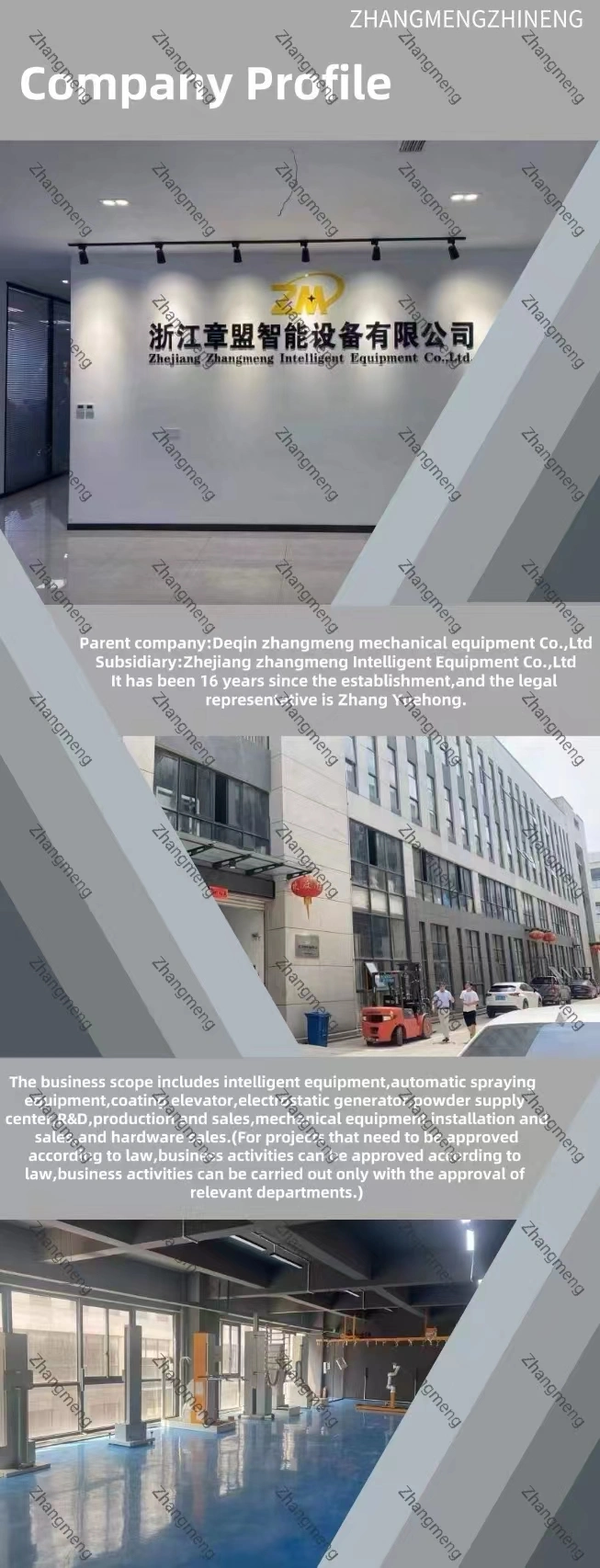

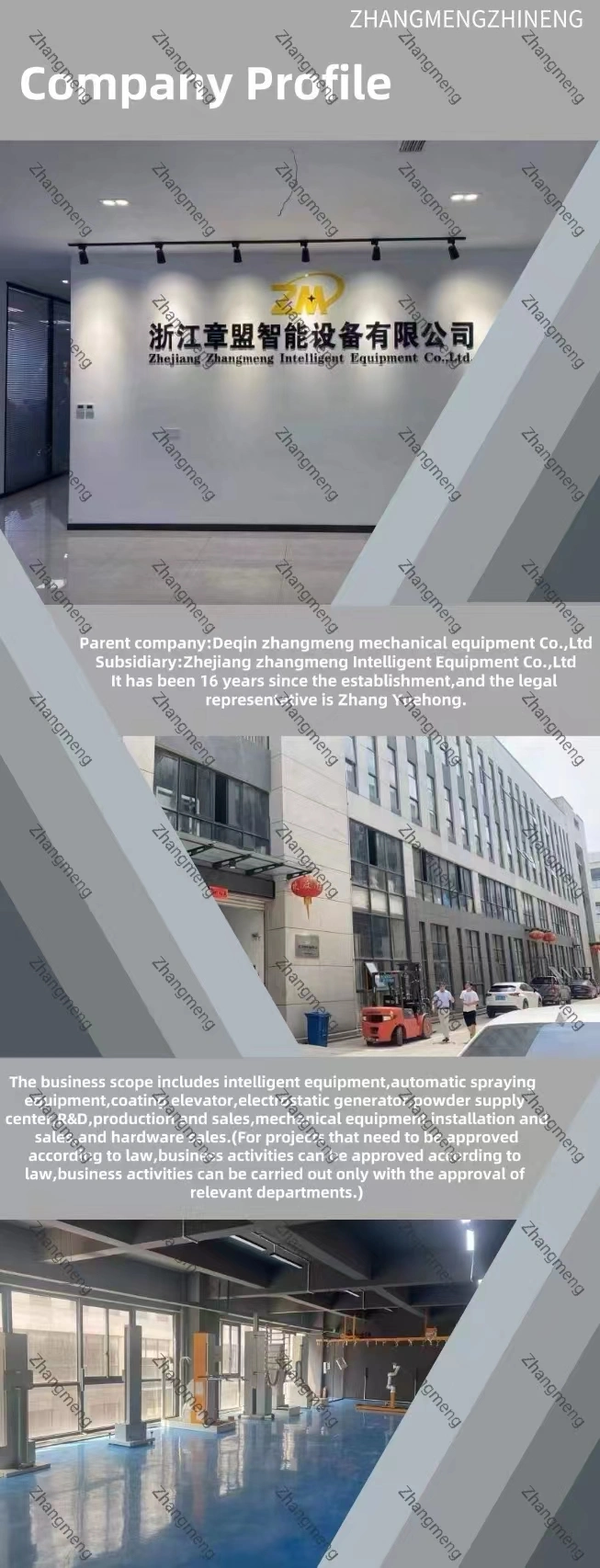

Paint spraying1,The basic principle of electrostatic sprayingElectrostatic spraying is to be painted as the positive electrode, grounded in everyday situations; paint atomization device as the negative electrode, connected to the power supply negative high voltage, so that in the two poles will become a high-voltage electrostatic field. As a result of the corona discharge at the cathode, the sprayed paint medium can be charged and further atomized. In accordance with the principle of "same-sex repulsion, opposites attract", the charged paint medium is subject to the electric field force (F = twist), the paint to be coated to form a ring effect, along the power line directional flow to the appearance of the positively charged object, piled into a layer of average, firmly attached to the film. Electrostatic painting technology can also be used positive corona discharge, but the critical voltage of negative corona discharge is lower than positive corona discharge, and more stable, less likely to generate sparks. In the usual scenario will be painted as a positive ground.2,Electrostatic spraying equipmentElectrostatic spraying equipment - electrostatic spray gun (including a spray gun, atomizing nozzle, an electrostatic generator, as well as a paint pump), electrostatic spray gun market application of more brands such as Seahorse, Yuanqi, Hongda, Iwata,Taiwan Seahorse, Yuanqi, Hongda because of the cost advantages (including after-sales maintenance costs), and technical parameters have been reached to meet a variety of products, paint spraying requirements. Paint spray gun atomization nozzle can be selected according to the different coatings, painted objects, such as TCN20 metal round nozzle, suitable for spraying transparent paint, fan-shaped nozzle for spraying large flat products, with magnetic round nozzle for spraying color paint, etc., nozzle selection is best to consult professional technicians, about the general high voltage generator power is generally between 30KV-80KV, and the general supply of Paint pump spraying pressure is generally in the 0.4MPA or so. In addition, electrostatic spraying equipment according to the different functions of manual electrostatic spraying and automatic electrostatic spraying, the principle is the same, electrostatic spraying is mainly installed in automated production lines, such as robots, reciprocating machines, but the flexibility is not as high as manual electrostatic spraying, many products must use manual electrostatic spraying to achieve the spraying requirements.3, the advantages of electrostatic spraying3.1, uniform and plump paint film, adhesion and decorative are good.3.2, high production efficiency, good labor conditions, multiple electrostatic spray gun fixed installation, to achieve multiple simultaneous spraying, easy to achieve semi-automatic or automated, compared with compressed air spraying, production efficiency than manual spraying more than 10 times higher, and completely free from manual spraying (painting) heavy labor, especially suitable for large-scale assembly line operations.3.3,Improve the utilization rate of paint, the utilization rate of paint materials up to 80 ~ 90%, generally compared to manual spraying to save about 60% of paint, reduce paint fog and pollution, and improve labor hygiene conditions.3.4, high quality paint film, good adhesion, especially uniform, glossy paint film.Water-rotation paint spraying roomThe water-rotation paint spraying room adopts upward air supply and downward air extraction, and the paint mist trapping device is underneath the spraying room, which is suitable for large and medium-sized workpieces. With water as the medium, it adopts the way of upward air supply and downward air extraction to make the paint mist and water fully mixed in the lower part of the spraying room. The plane of the water-rotating paint spraying room can be large or small, suitable for large and medium-sized workpieces of advanced spraying.The working principle of the water-rotating paint spraying room: fresh air is sent into the equal pressure chamber at the top of the water-rotating paint spraying room through the air conditioning air supply device, and after the equal flow regulator and filter layer, it is evenly sent into the chamber with the end wind speed of 0.45m/s, from top to bottom, the workpiece is placed into the equal flow layer with a certain wind speed, so that the splashing waste paint mist is pressed into the water-rotating paint spraying room water spinner, water is atomized under the impact of high-speed airflow and waste paint Mist fully mixed, so that the paint mist is attracted to the water and take away, the air containing water and then through the air-water separation, clean air sent into the atmosphere by the exhaust system, the purification rate of paint mist ≥ 98%; and the water containing paint mist into the circulation pool, through coagulation purification (water regularly added special coagulant) sent by the circulation pump to the paint room recycling, floating paint slag regularly fished out after deep burial or incineration treatment .Application range of water spin spray paint room: household appliances, bicycles, household and commercial steel furniture, automobiles, motorcycle parts and surface spraying, instrumentation shells, electrical cabinets, machinery, sports equipment, etc.After sales guarantee:(1) After 16 years of entrepreneurship, tens of thousands of sets of equipment have been delivered around the world. How to ensure after-sales service? First of all, our products are all modular components. Each unit is an independent individual, which can be replaced by quick plugging. No door-to-door service is required, but users can operate by themselves.(2) We have a professional team to provide all-weather support for one-to-one quick connection and feedback

Packaging: As long as it is for export, we use fumigated wood packaging to avoid damage.

exhibition